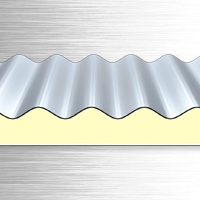

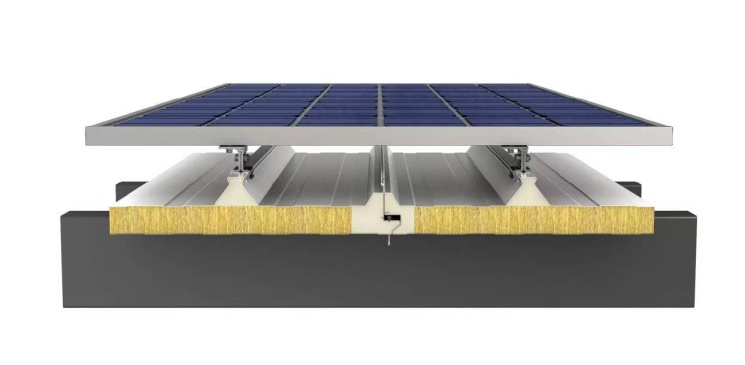

Air condition panel

Panels

Applied Images:

Mobile|WeChat|WhatsApp: (+86)18553303756

Email: sales@inovpu.com,kevin@inovpu.com

Product Introduction:

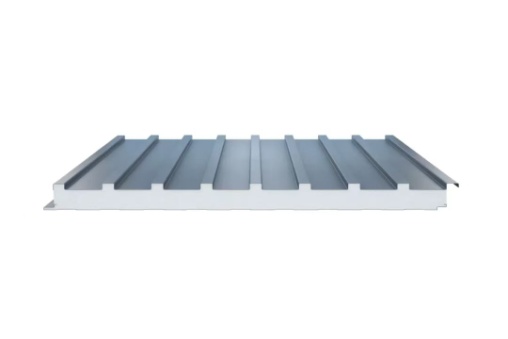

Polyurethane panel primarily consist of rigid foam as the core material, with both sides customizable for different composite materials. Classified by application, they include building insulation panels, industrial insulation panels, and decorative panels. Surface treatments encompass color-coated steel composite polyurethane panel, aluminum composite polyurethane panel, and stainless steel composite polyurethane panel. Shapes are categorized into flat panels and sandwich panels (e.g., corrugated panel). Production processes feature batch and continuous methods, with flame retardant ratings B1, B2, and B3 available as required.

Performance and application:

1. Excellent thermal insulation performance: Polyurethane panel have a very low thermal conductivity, making them an efficient insulating material. For example, in the field of building insulation, walls using polyurethane insulation panel can reduce heat transfer by 70% to 80% compared to traditional wall materials, effectively lowering building energy consumption and improving indoor thermal comfort.

2. Excellent Mechanical Properties: The polyurethane rigid foam core material boasts high strength and hardness, capable of withstanding external impacts. Its composite structure also demonstrates superior performance in bending and compressive resistance. For instance, in industrial insulation applications where equipment weight or occasional collisions are required, polyurethane panels provide robust mechanical protection.

3. High waterproof and airtight: Due to its closed hole structure, polyurethane board has good waterproof properties, can effectively prevent water infiltration. In addition, its airtight performance is also excellent, which can reduce air leakage in the building and further improve the insulation effect.

4. Adjustable fire performance: by adding flame retardants, polyurethane panels can reach different fire resistance grades, which makes it can be used in different places with different fire requirements.

5. Diverse Decorative Options: When combined with various surface materials, polyurethane panels can create multiple decorative effects. For instance, color-coated steel plates integrated with polyurethane panels offer vibrant color options that meet aesthetic requirements for building facades. Aluminum plates combined with polyurethane panels exhibit metallic textures, making them ideal for industrial or commercial buildings where high-quality visual appearance is essential.

Technical Indicators:

Grade | R3101 | R3202 | R3203 | R3204 | R3200 | DonPanel 415 | DonPanel 421 |

|---|---|---|---|---|---|---|---|

| Product Type | Metal Decorative Panel | Exterior Wall Panel | Pentane Multi-Component Continuous Panel | Air Conditioning Panel | Corrugated Panel | ||

| Blowing Agent Type | CH | CH | CH | CH | HFC-245fa | H 2 O | |

| POL:ISO | 100:100-130 | 100:120-130 | 100: 105-110 | 100: 150-200 | 100: 110 | 100: 150 | |

| Appearance | Colorless to yellowish brown transparent liquid | Colorless to yellowish brown transparent liquid | Colorless to yellowish brown transparent liquid | Colorless to yellowish brown transparent liquid | Colorless to yellowish brown transparent liquid | Colorless to yellowish brown transparent liquid | |

| Molding Density Kg/m3 | ≥38 | ≥38 | ≥38 | ≥38 | ≥38 | ≥40 | ≥25 |

| Thermal Conductivity W/m·k | ≤0.024 | ≤0.024 | ≤0.024 | ≤0.024 | ≤0.022 | — |